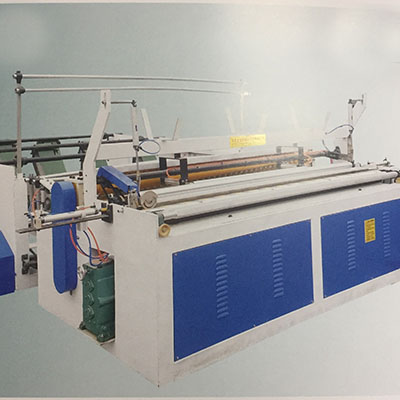

The toilet paper rewinder uses a series of mechanical devices and control systems to unfold the large axis raw paper placed on the paper return rack, guided by the paper guide roller, and enters the rewinding section. During the rewinding process, the raw paper is tightly and evenly rewound into a certain specification roll of toilet paper by adjusting parameters such as the speed, pressure, and tension of the rewinding roller. At the same time, some rewinding machines also have functions such as embossing, punching, and glue spraying to meet the diverse needs of different users for toilet paper products.

Common models

1880 type: maximum paper size 2200mm, minimum paper size 1000mm, suitable for small and medium-sized enterprises as well as individuals, with advantages in raw material selection, which can increase production while reducing paper product loss.

2200 model: The 2200 model toilet paper rewinder made of pure steel plate material runs stably and is suitable for beginners with small initial investment and small footprint. It can be paired with manual paper cutters and water-cooled sealing machines to produce approximately two and a half tons of toilet paper in 8 hours.

3000 type: With a large output of about 6 tons in 8 hours, it is suitable for customers who pursue output and do not want to replace equipment. It is generally equipped with automatic paper cutting machines and automatic packaging machines, and operates on a full assembly line to save labor and losses.

Post time: Dec-27-2024