Online Exporter Tissue Paper Making Machine - Toilet Paper Machine Cylinder Mould Type – Dingchen

Online Exporter Tissue Paper Making Machine - Toilet Paper Machine Cylinder Mould Type – Dingchen Detail:

| 1.Raw material | Waste books paper |

| 2.Output paper | Toilet paper;Tissue paper |

| 3.Output paper weight | 15-30 g/m2 |

| 4.Output paper width | 1200-3200mm |

| 5.Wire width | 1450-3650 mm |

| 6.Capacity | 2-15 Tons Per Day |

| 7. Working speed | 50-180m/min |

| 8. Design speed | 80-210m/min |

| 9.Rail gauge | 1800-4300 mm |

| 10.Drive way | Alternating current frequency conversion adjustable speed, sectional drive |

| 11.Layout | Left or right hand machine |

Waste books paper →Stock preparation system→Cylinder mould part→Dryer part→Reeling part

Requirements for Water, electricity, steam, compressed air and lubrication:

1.Fresh water and recycled use water condition:

Fresh water condition:clean,no color,low sand

Fresh water pressure used for boiler and cleaning system:3Mpa、2Mpa、0.4Mpa(3 kinds) PH value:6~8

Reuse water condition:

COD≦600 BOD≦240 SS≦80 ℃20-38 PH6-8

2. Power supply parameter

Voltage:380/220V±10%

Controlling system voltage:220/24V

Frequency:50HZ±2

3.Working steam pressure for dryer ≦0.5Mpa

4. Compressed air

● Air source pressure:0.6~0.7Mpa

● Working pressure:≤0.5Mpa

● Requirements: filtering、degreasing、dewatering、dry

Air supply temperature:≤35℃

1.Raw material consumption: 1.2 tons waste paper for producing 1 ton paper

2.Boiler fuel consumption: Around 120 Nm3 natural gas for producing 1 ton paper

Around 138 liter diesel for making 1 ton paper

Around 200kg coal for making 1 ton paper

3.Power consumption: around 250 kwh for producing 1 ton paper

4.Water consumption: around 5 m3 fresh water for making 1 ton paper

5.Operating personal: 7 workers/shift, 3 shifts/24hours

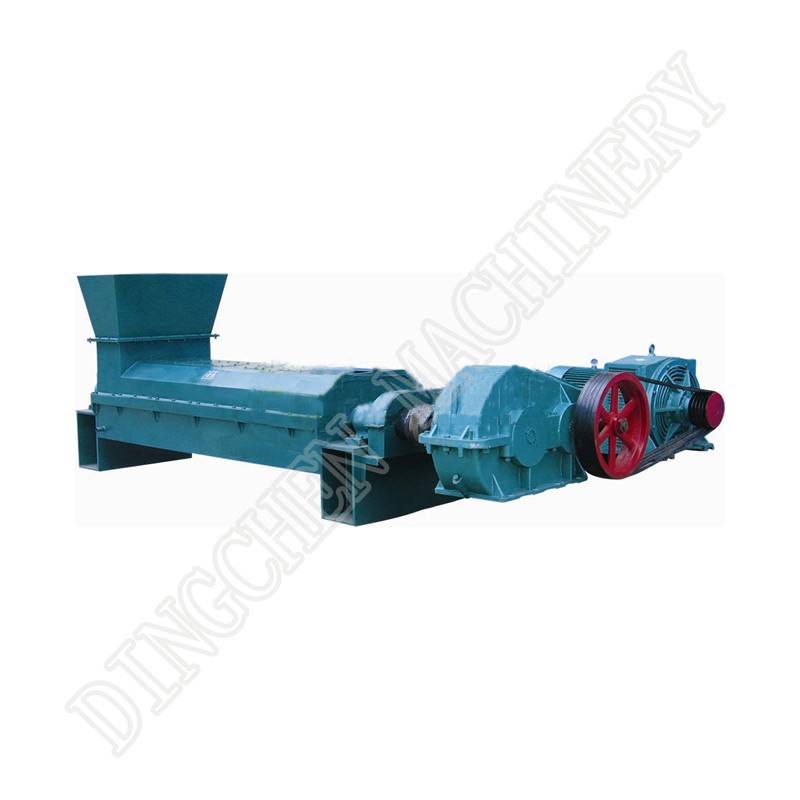

Product detail pictures:

Related Product Guide:

Sticking to the perception of "Creating products of top of the range and earning mates with people today from all over the world", we constantly put the desire of consumers in the first place for Online Exporter Tissue Paper Making Machine - Toilet Paper Machine Cylinder Mould Type – Dingchen , The product will supply to all over the world, such as: Orlando, Brasilia, Ecuador, We have been seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.